Welcome, dear reader! In the world of manufacturing, efficiency and accuracy are key factors for success. This is where Process Manufacturing ERP software comes into play, offering a wide range of benefits for companies looking to streamline their operations. From improving inventory management to enhancing quality control, this type of software can revolutionize the way businesses operate. Let’s explore the advantages of Process Manufacturing ERP software and how it can help your company thrive in today’s competitive market.

Features of Process Manufacturing ERP Software

Process manufacturing ERP software is specifically designed to meet the unique needs of companies in industries such as food and beverage, pharmaceuticals, chemicals, and other related sectors. These software solutions offer a comprehensive set of features to help streamline and optimize the production process. Here are some key features of process manufacturing ERP software:

1. Recipe Management: One of the most important features of process manufacturing ERP software is recipe management. This functionality allows users to create and manage complex recipes for products, including ingredients, quantities, production steps, and quality control parameters. Recipe management helps ensure consistency in product quality and helps manufacturers comply with regulatory requirements. It also enables companies to easily scale production based on demand fluctuations and make adjustments to recipes as needed.

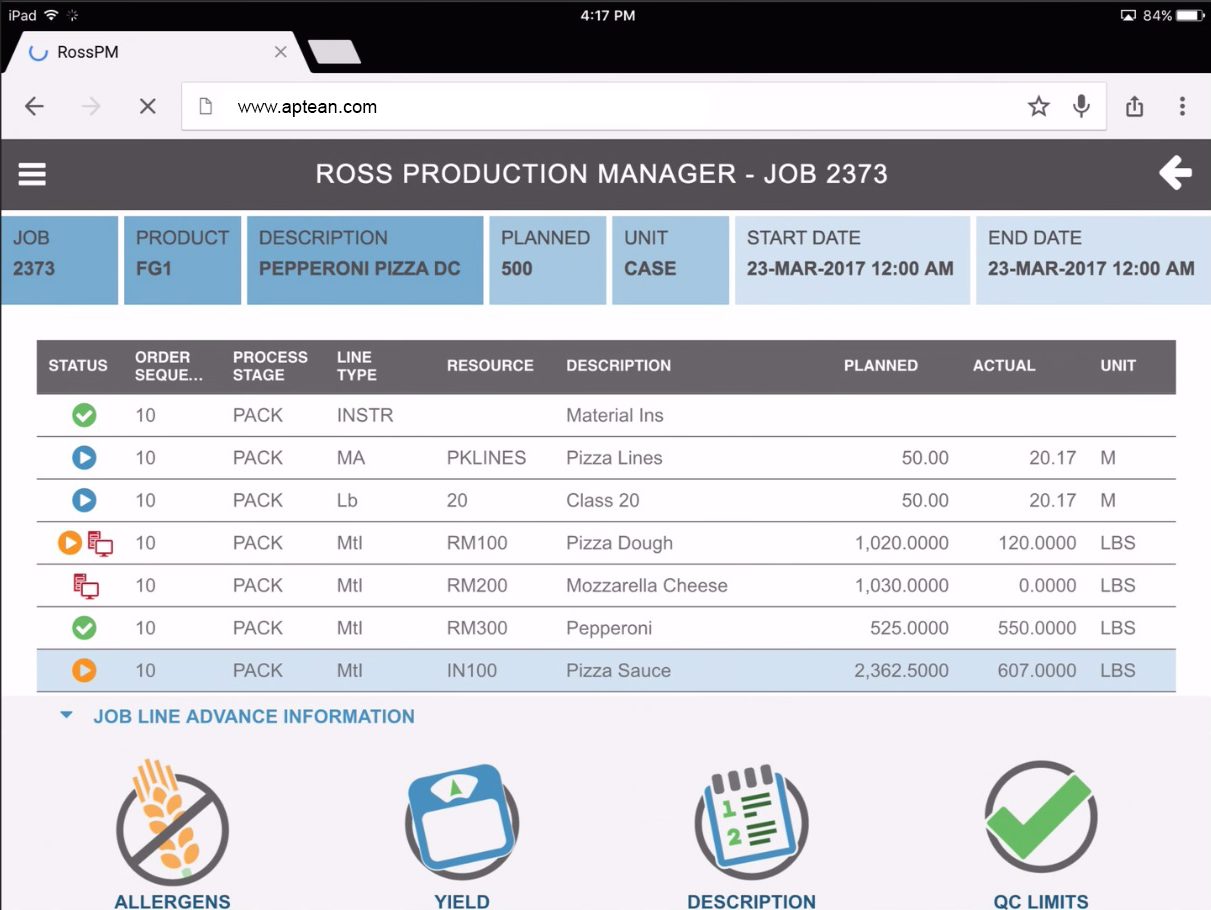

2. Batch Processing: Process manufacturing ERP software includes batch processing capabilities, allowing companies to manage and track the production of products in batches. This feature is essential for industries where products are produced in large quantities and require strict quality control measures. Batch processing helps ensure traceability, enables efficient production scheduling, and allows for real-time monitoring of production progress.

3. Inventory Management: Another key feature of process manufacturing ERP software is inventory management. This functionality helps companies track raw materials, ingredients, and finished goods throughout the production process. Inventory management modules offer real-time visibility into inventory levels, enable efficient stock replenishment, and help minimize stockouts or overstock situations. This feature is crucial for process manufacturers to maintain optimal inventory levels and meet customer demand.

4. Quality Control: Process manufacturing ERP software includes robust quality control features to help manufacturers maintain product quality standards. Quality control modules allow companies to define quality parameters, perform inspections and tests at various stages of production, and track compliance with regulatory standards. This feature helps prevent defects, reduce rework, and minimize product recalls, ultimately improving customer satisfaction and brand reputation.

5. Compliance Management: Process manufacturing ERP software helps companies ensure compliance with industry regulations and standards. These software solutions offer built-in functionalities for managing regulatory requirements, certifications, and documentation. Compliance management features enable companies to streamline regulatory reporting, reduce the risk of non-compliance penalties, and maintain a positive relationship with regulatory agencies.

6. Production Planning and Scheduling: Process manufacturing ERP software provides tools for efficient production planning and scheduling. These features allow companies to optimize production processes, allocate resources effectively, and minimize production downtime. Production planning modules help manufacturers forecast demand, create production schedules, and balance production capacities to meet customer orders on time.

7. Real-Time Analytics and Reporting: Process manufacturing ERP software offers advanced analytics and reporting capabilities to help companies gain insights into their production processes. These features provide real-time visibility into key performance indicators, production metrics, and inventory levels. Analytics tools allow companies to identify trends, optimize production efficiency, and make data-driven decisions to drive business growth.

In conclusion, process manufacturing ERP software is essential for companies in industries with complex production processes. These software solutions offer a wide range of features to help streamline operations, ensure product quality, and maintain regulatory compliance. By leveraging the key features mentioned above, process manufacturers can enhance their competitiveness, improve productivity, and drive business success.

Benefits of Implementing Process Manufacturing ERP Software

Process manufacturing ERP software offers a wide range of benefits for businesses in the manufacturing industry. From improving efficiency to enhancing quality control, implementing ERP software can have a significant impact on the overall operations of a company.

One of the key benefits of process manufacturing ERP software is improved efficiency. By streamlining processes and automating repetitive tasks, ERP software can help reduce manual errors and speed up production times. This in turn can lead to cost savings for the company and increased productivity for employees.

Another advantage of implementing process manufacturing ERP software is enhanced quality control. With real-time data tracking and reporting capabilities, ERP systems allow businesses to monitor the quality of their products throughout the manufacturing process. This helps to identify and address any issues early on, preventing defects and ensuring that products meet strict quality standards.

Furthermore, process manufacturing ERP software can also improve inventory management. By providing visibility into inventory levels, ERP systems help businesses optimize their stock levels and reduce excess inventory. This not only helps to lower carrying costs but also ensures that products are always available when needed, preventing stockouts and lost sales opportunities.

Additionally, implementing process manufacturing ERP software can lead to better decision-making. With access to real-time data and analytics, businesses can make informed decisions about production schedules, resource allocation, and supply chain management. This helps companies respond quickly to changing market conditions and customer demands, improving overall competitiveness in the marketplace.

Lastly, process manufacturing ERP software can also enhance regulatory compliance. Many industries, such as the food and beverage sector, are subject to strict regulations and quality standards. ERP systems help businesses track and document compliance with these regulations, reducing the risk of fines and penalties for non-compliance.

In conclusion, the benefits of implementing process manufacturing ERP software are numerous and can have a significant impact on a company’s operations. From improved efficiency and quality control to better inventory management and decision-making, ERP systems offer a comprehensive solution for businesses looking to streamline their manufacturing processes and stay competitive in today’s market.

Key Considerations for Selecting Process Manufacturing ERP Software

When selecting process manufacturing ERP software, there are several key considerations that need to be taken into account to ensure the system meets the specific requirements of your industry. Here are some important factors to consider:

1. Industry-Specific Functionality:

One of the most crucial considerations when choosing process manufacturing ERP software is to ensure that it offers industry-specific functionality. Process manufacturing industries have unique requirements and processes that generic ERP systems may not be able to fully support. Look for software that is tailored to the needs of your specific industry, whether it’s food and beverage, chemicals, pharmaceuticals, or any other sector within process manufacturing.

2. Scalability and Flexibility:

Another vital consideration is the scalability and flexibility of the ERP software. As your business grows and evolves, the software should be able to accommodate increased data volumes, users, and processes without a significant impact on performance. Additionally, the system should be flexible enough to adapt to changing business requirements and industry trends. Make sure the software can easily integrate with other systems and support future growth without the need for costly upgrades or customizations.

3. Regulatory Compliance and Quality Control:

Compliance with industry regulations and quality control standards is paramount in process manufacturing. The ERP software you choose should have robust features to help you meet regulatory requirements and maintain high-quality standards. Look for functionality that enables you to track and trace raw materials, monitor production processes, and ensure product consistency and safety. The software should also support batch and lot tracking, manage recipe formulations, and provide tools for quality assurance and control.

4. Inventory Management and Traceability:

Efficient inventory management and traceability are essential for process manufacturing companies to minimize waste, optimize production, and meet customer demands. The ERP software should offer comprehensive inventory management capabilities, including real-time tracking of raw materials, work-in-progress, and finished goods. It should also provide tools for optimizing inventory levels, reducing lead times, and improving supply chain visibility. Ensure the software has robust traceability features that allow you to trace products throughout the production process and quickly identify any issues or recalls.

5. Integration with Supply Chain and Financial Systems:

Process manufacturing ERP software should seamlessly integrate with your supply chain and financial systems to streamline operations, improve collaboration, and ensure accurate financial reporting. Look for software that offers built-in modules or APIs for integrating with third-party systems such as warehouse management, procurement, and accounting. This integration will help you achieve end-to-end visibility into your processes, reduce manual data entry errors, and enhance decision-making based on real-time data.

Overall, when selecting process manufacturing ERP software, it’s important to consider the unique needs of your industry, the scalability and flexibility of the system, compliance with regulations and quality control standards, efficient inventory management, traceability, and seamless integration with supply chain and financial systems. By carefully evaluating these key considerations, you can choose an ERP solution that meets your specific requirements and supports the long-term growth and success of your business.

Case Studies of Successful Process Manufacturing ERP Software Implementations

Implementing process manufacturing ERP software can be a complex and challenging task for companies. However, with the right approach and proper planning, many organizations have succeeded in successfully implementing this type of software. Here are a few case studies of successful process manufacturing ERP software implementations:

1. ABC Chemicals Inc.

ABC Chemicals Inc. is a leading manufacturer of specialty chemicals for various industries. The company decided to implement process manufacturing ERP software to streamline its operations and improve overall efficiency. By integrating all of its processes into one system, ABC Chemicals was able to see significant improvements in inventory management, production planning, and quality control. The software also helped the company to comply with strict regulatory requirements in the chemical industry.

2. XYZ Foods Co.

XYZ Foods Co. is a food processing company that produces a wide range of products for both domestic and international markets. The company faced challenges with inventory tracking, recipe management, and order processing. After implementing process manufacturing ERP software, XYZ Foods Co. was able to automate these processes and gain better visibility into its supply chain. This led to improved production scheduling, reduced waste, and increased customer satisfaction.

3. LMN Pharmaceuticals Ltd.

LMN Pharmaceuticals Ltd. is a pharmaceutical company that specializes in the manufacturing of generic drugs and over-the-counter medications. The company needed a solution to manage its complex manufacturing processes and comply with strict regulatory standards. By implementing process manufacturing ERP software, LMN Pharmaceuticals was able to achieve better control over its production processes, ensure product quality, and maintain compliance with industry regulations. The software also helped the company to track and trace its products throughout the supply chain.

4. Mega Beverages Corp.

Mega Beverages Corp. is a beverage manufacturing company that produces a variety of soft drinks and energy drinks. The company struggled with issues related to batch processing, recipe formulation, and demand planning. After implementing process manufacturing ERP software, Mega Beverages Corp. saw significant improvements in its production efficiency and product quality. The software enabled the company to automate its batch processing, optimize recipe management, and accurately forecast demand. As a result, Mega Beverages was able to reduce production costs, increase productivity, and expand its market reach.

Overall, these case studies demonstrate the benefits of implementing process manufacturing ERP software in various industries. By leveraging the capabilities of this type of software, companies can improve their operational efficiency, enhance product quality, and achieve regulatory compliance. With the right strategy and approach, organizations can successfully implement process manufacturing ERP software to drive growth and success in today’s competitive business environment.

Future Trends in Process Manufacturing ERP Software Innovations

As technology continues to advance, the future of process manufacturing ERP software is constantly evolving. Here are some key trends to look out for in the coming years.

1. Automation: One of the biggest trends in process manufacturing ERP software is the increased focus on automation. As more and more processes become automated, businesses are looking for ways to streamline their operations and reduce manual processes. This can include everything from automated data entry to robotic process automation, which can help improve efficiency and reduce costs.

2. Integration with IoT: Another trend in process manufacturing ERP software is the integration with the Internet of Things (IoT). With IoT devices becoming more prevalent in manufacturing plants, ERP systems are looking to incorporate this data into their platforms. By connecting IoT devices to ERP systems, manufacturers can gather real-time data, improve decision-making, and optimize production processes.

3. Predictive Analytics: Predictive analytics is also becoming a key feature in process manufacturing ERP software. By using advanced algorithms and machine learning, ERP systems can analyze historical data to predict future trends and outcomes. This can help manufacturers identify potential issues before they occur, improve forecasting accuracy, and make more informed business decisions.

4. Cloud-Based Solutions: Cloud-based ERP systems are gaining popularity in the process manufacturing industry. With the ability to access data from anywhere, at any time, cloud-based solutions offer flexibility and scalability that traditional on-premise systems cannot match. This trend is expected to continue as more manufacturers look for ways to modernize their operations and improve collaboration among remote teams.

5. Blockchain Technology: One of the most exciting trends in process manufacturing ERP software is the integration of blockchain technology. Blockchain is a decentralized, secure, and transparent digital ledger that can help manufacturers track products, transactions, and processes in real-time. By using blockchain technology, manufacturers can ensure the authenticity of their products, increase supply chain visibility, and improve traceability throughout the production process.

Overall, the future of process manufacturing ERP software is bright, with innovations like automation, IoT integration, predictive analytics, cloud-based solutions, and blockchain technology leading the way. By embracing these trends, manufacturers can stay ahead of the competition, improve efficiency, and drive growth in the ever-changing manufacturing industry.

Originally posted 2025-02-06 14:00:00.