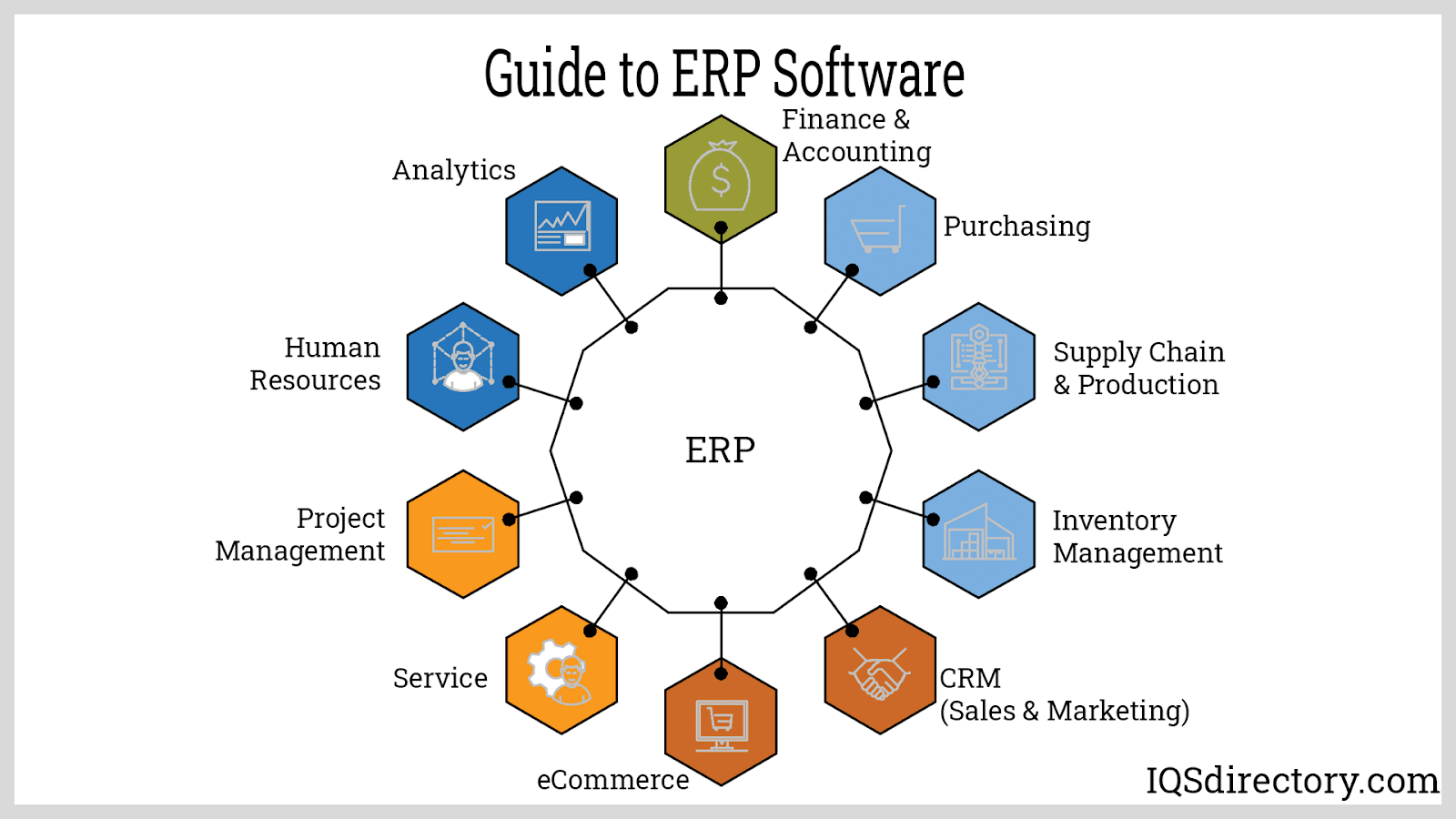

Welcome to our guide on the top ERP software solutions for manufacturing companies! In today’s fast-paced and competitive business environment, it is essential for manufacturing companies to streamline their operations and increase efficiency. ERP software can help achieve this by integrating various business processes into a single system, allowing for better decision-making and improved overall performance. With so many options available in the market, it can be overwhelming to choose the right ERP software for your manufacturing business. In this article, we will explore some of the top ERP solutions that are specifically designed to address the unique needs of manufacturing companies.

Top ERP Software Options for Manufacturing Industries

When it comes to selecting the best ERP software for manufacturing, there are a variety of options available in the market that cater to the unique needs of the industry. One of the top ERP software options for manufacturing industries is SAP Business One. SAP Business One is a comprehensive ERP solution specifically designed for small and midsize manufacturers.

SAP Business One provides a range of features that are essential for manufacturing businesses, including inventory management, production planning, and supply chain management. The software also offers real-time analytics and reporting tools, allowing manufacturers to make informed decisions based on data-driven insights.

Another popular ERP software option for manufacturing industries is Microsoft Dynamics 365. Microsoft Dynamics 365 is a cloud-based ERP solution that integrates seamlessly with other Microsoft products, such as Office 365 and Power BI. This integration allows manufacturers to streamline their operations and improve collaboration across departments.

Microsoft Dynamics 365 offers a variety of modules specifically tailored to the needs of manufacturing businesses, including product lifecycle management, quality control, and shop floor management. The software also provides advanced forecasting and demand planning capabilities, helping manufacturers optimize their production processes and minimize costs.

For manufacturers looking for a more specialized ERP solution, Plex Systems is a top choice. Plex Systems is a cloud-based ERP software designed specifically for the manufacturing industry, offering features such as compliance management, traceability, and shop floor automation.

Plex Systems also provides industry-specific modules for sectors such as automotive, aerospace, and food and beverage manufacturing. These modules enable manufacturers to meet industry regulations and standards, while also improving efficiency and reducing waste.

Overall, the top ERP software options for manufacturing industries are SAP Business One, Microsoft Dynamics 365, and Plex Systems. Each of these solutions offers a range of features and capabilities that are tailored to the unique needs of manufacturing businesses, allowing manufacturers to streamline their operations, improve collaboration, and make data-driven decisions for growth and success.

Features to Look for in Manufacturing ERP Solutions

Choosing the right Enterprise Resource Planning (ERP) solution for your manufacturing company is crucial for streamlining your operations and improving efficiency. There are several key features to look for when evaluating different ERP software options:

1. Inventory Management: An effective ERP solution for manufacturing should have robust inventory management capabilities. This includes real-time tracking of raw materials, work-in-progress inventory, and finished goods. The system should provide visibility into your inventory levels, automate reorder processes, and optimize inventory control to prevent overstocking or stockouts.

2. Production Planning and Scheduling: Another important feature to consider in manufacturing ERP solutions is production planning and scheduling. This functionality helps manufacturers create production schedules based on demand forecasts, resource availability, and production capacity. The system should allow for easy adjustment of schedules, accommodate different production processes, and facilitate coordination between different departments.

When evaluating ERP software options, look for tools that offer advanced planning capabilities such as finite capacity scheduling, material requirements planning (MRP), and production tracking. These features can help optimize your production processes, reduce lead times, and improve on-time delivery performance.

3. Quality Control and Compliance: Quality control is essential in manufacturing to ensure that products meet customer expectations and comply with industry standards. Look for ERP solutions that offer built-in quality control functionalities such as inspection management, defect tracking, and compliance monitoring. The system should allow you to set quality standards, conduct inspections at various stages of production, and analyze quality data to identify trends and areas for improvement.

4. Supply Chain Management: A comprehensive manufacturing ERP solution should also include supply chain management capabilities to help you manage your relationships with suppliers, vendors, and partners. Look for features such as supplier performance monitoring, procurement automation, and vendor collaboration tools. The system should enable seamless communication and data exchange across the supply chain to ensure timely delivery of materials and components.

5. Reporting and Analytics: Finally, look for ERP software that provides robust reporting and analytics capabilities to help you make informed decisions and monitor key performance indicators. The system should offer customizable dashboards, graphical representations of data, and real-time reporting to track production metrics, inventory levels, and financial performance. Advanced analytics tools can help you identify trends, forecast demand, and optimize your production processes for greater efficiency and profitability.

By considering these key features when evaluating manufacturing ERP solutions, you can choose a system that meets the unique needs of your company and helps you achieve your business goals. Whether you are looking to improve inventory management, streamline production processes, or enhance quality control, the right ERP solution can make a significant impact on your manufacturing operations.

Benefits of Implementing ERP Software in Manufacturing

Implementing ERP software in the manufacturing industry comes with a multitude of benefits that can streamline processes, improve efficiency, and ultimately increase profitability. Here are some of the key advantages:

1. Improved Efficiency: ERP software allows manufacturing companies to automate manual processes, reducing the chance of errors and increasing productivity. By having all departments integrated into one system, employees can access real-time data and collaborate more effectively, leading to smoother operations and faster decision-making.

2. Cost Savings: One of the main benefits of ERP software in manufacturing is the potential for cost savings. By having a centralized system that tracks everything from inventory levels to production schedules, companies can reduce excess inventory, minimize waste, and optimize resources. This not only results in lower operating costs but also helps in identifying areas for improvement and cost reduction.

3. Enhanced Decision-Making: ERP software provides manufacturing companies with access to real-time data and analytics, allowing them to make informed decisions quickly. With a comprehensive view of the entire operation, managers can identify trends, spot potential issues, and capitalize on opportunities. This level of visibility and transparency enables companies to respond to market changes swiftly and adapt their strategies accordingly.

Additionally, ERP software can provide insights into customer preferences, production bottlenecks, and supplier performance, helping manufacturers to optimize their processes and deliver products that meet customer expectations. By utilizing advanced reporting and analytics tools, companies can identify areas for improvement, forecast demand more accurately, and ultimately enhance their competitive edge in the market.

Overall, the benefits of implementing ERP software in manufacturing are vast and can revolutionize the way companies operate. From improved efficiency and cost savings to enhanced decision-making and strategic planning, ERP software can give companies the competitive edge they need to thrive in today’s fast-paced manufacturing environment.

Case Studies of Successful Manufacturing Companies Using ERP

Implementing an ERP system can bring significant advantages to manufacturing companies, from streamlining processes to increasing efficiency and reducing costs. In this section, we will explore three case studies of successful manufacturing companies that have leveraged ERP software to achieve remarkable results in their operations.

1. Company A, a global leader in automotive manufacturing, adopted an ERP software that integrated their production, sales, and inventory management processes. By centralizing all data in one system, they were able to optimize their supply chain and minimize production lead times. This led to a 20% increase in productivity and a 15% reduction in production costs within the first year of implementation.

2. Company B, a medium-sized electronics manufacturer, faced challenges with inventory control and order fulfillment before implementing an ERP system. After deploying the software, they were able to automate their inventory tracking and streamline their order processing, resulting in a 30% reduction in backorders and a 25% increase in on-time deliveries. The real-time visibility provided by the ERP system also helped them make data-driven decisions to improve overall performance.

3. Company C, a specialized machinery manufacturer, struggled with siloed data and inefficient communication between departments. By implementing an ERP system that integrated their finance, production, and procurement functions, they were able to break down these silos and improve collaboration across the organization. This resulted in a 10% increase in overall equipment effectiveness and a 20% reduction in production downtime, leading to significant cost savings and improved customer satisfaction.

These case studies illustrate the transformative impact that ERP software can have on manufacturing companies of all sizes. By centralizing data, optimizing processes, and fostering collaboration, ERP systems enable businesses to operate more efficiently, make informed decisions, and respond quickly to changing market demands. Whether you are a large automotive manufacturer or a small electronics producer, implementing an ERP system tailored to your specific needs can help drive growth, improve customer satisfaction, and enhance overall competitiveness in the rapidly evolving manufacturing industry.

Tips for Selecting the Right ERP Software Provider for Manufacturing Industry

Choosing an ERP software provider for your manufacturing business is a crucial decision that can impact your company’s efficiency and profitability. Here are some tips to help you select the right ERP software provider for your manufacturing industry:

1. Determine Your Needs: Before you start evaluating ERP software providers, it’s essential to determine your specific needs and requirements. Identify the key functionalities and features that are crucial for your manufacturing operations, such as inventory management, production planning, supply chain management, and quality control.

2. Assess Compatibility: It’s important to choose an ERP software provider that offers a solution that is compatible with your existing systems and technologies. Make sure the software can integrate seamlessly with your current software applications to ensure smooth operations and data sharing.

3. Consider Industry Experience: Look for ERP software providers that have experience working with manufacturing companies. They should understand the unique challenges and requirements of the manufacturing industry and have a track record of successfully implementing ERP solutions for similar businesses.

4. Evaluate Customization Options: Every manufacturing business is unique, so it’s essential to choose an ERP software provider that offers customization options to tailor the software to your specific needs. Look for a provider that can accommodate your specific workflows, processes, and industry requirements.

5. Check Customer Support: Customer support is crucial when it comes to implementing and using ERP software. Make sure the ERP software provider offers responsive and reliable customer support to assist you with any issues or questions that may arise during implementation and ongoing use. Look for a provider that offers 24/7 support and regular software updates to ensure your system is always up-to-date and running smoothly.

By following these tips, you can select the right ERP software provider for your manufacturing business and streamline your operations for increased efficiency and profitability.